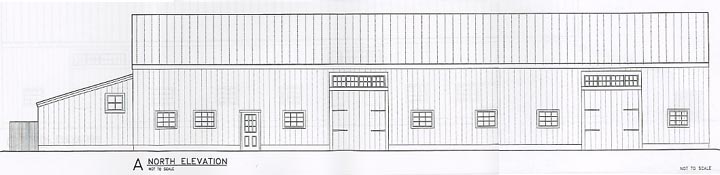

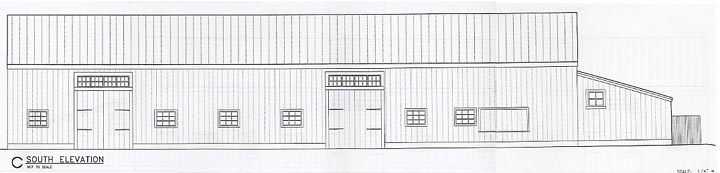

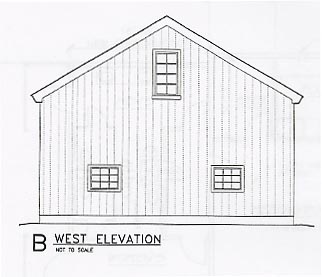

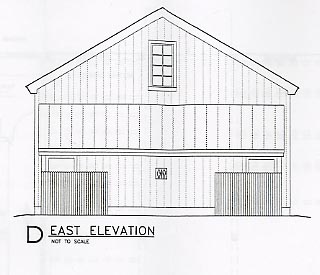

Reassembling the Lawrence Barn

Construction Plan

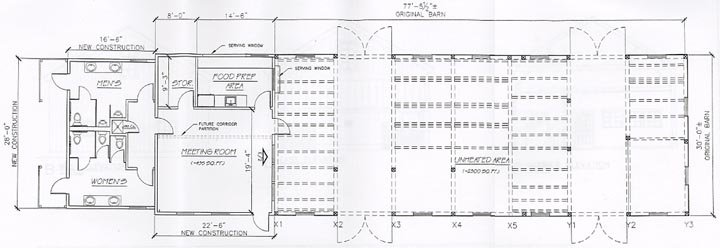

(Drawn by BMA Architects of Amherst, New Hampshire)

Plan Interior

A major goal of the Lawrence Barn project was to give every person in the town the opportunity to work on the project is some way in order to allow them to feel that it was indeed a “community” center. The following is a list of some of the construction tasks that were done by volunteers:

- Site Plan & Survey Work: contributed by Bob Cormier and Cuoco & Cormier

- Demolition of the old building: contributed at reduced rates by Doug Orde and Hollis Construction

- Excavation and Foundation Work: The majority of this work was contributed by Amos White and Homes by Paradise

- Move beams back to Hollis:

- The restored beams were loaded in Berwick, Maine, by Arron Sturgis’ crew, and unloaded in Hollis under his supervision

- Trucking was by Honi Glover, Balcom Trucking, and by Law Trucking

- Crane work was contributed by Herm Stickney and Pioneer Tree

- Ship Lap sheathing:

- Arron’s crew did the roof and volunteers did all the walls, which were sheathed prior to installation of the SIPS panels

- The pine boards for both the interior ship lap sheathing and the exterior board and battens were provided at below cost by Lorin Rydstrom of Seaboard International

- SIP Installation: Mostly by the Panel Pros. Arron’s crew was there to make the connections from the old frame to the new SIPS.

- Install Windows and doors: The windows and small doors were cut into the SIPS panel and then flashed and trimmed using pine boards.

- Exterior Batten and Boards: We used rough vertical pine boards that are 10” and 12” wide. The 1x5 batten were nailed over the SIP panel (& TYVEC) and then the pine board. The walls are about 15 feet high. Care was taken to keep them plumb and to finish neatly with large boards at corners and doorways.

- Frame end of barn, bathroom shed and entry area:

- Keith Adamyck of Adamyck Homes coordinated the framing work

- The building materials for this and other areas of work were provided at cost by Jerry Eckman and Reeds Ferry Lumber

- Standing Seam Metal Roofing: The roofing labor was contributed by Jeff Taylor and Viking Roofing. He also provided the materials at cost.

- Plasterboard Walls & Ceilings: The sheetrock labor and materials were donated by David McCartney and Gemini Construction

- Install Kitchen:

- The cabinets were donated by John Testa of Kitchen Concepts

- Other members of the kitchen team included Denise April and Chuck Mussin

- Exterior Staining: Cabot Stain Company contributed the stain

- Roger Skillings and Skillings Well Company donated the labor and materials for the pump and equipment necessary to develop the water pressure on the site

- Plumbing: Joe Cianci and J.J. Ciampa & Son provided the plumbing materials and labor at reduced rate and J.J. Ciampa & Son provided the plumbing materials and labor at reduced rate

- Electrical: Paul Armstrong of Dunwell Electric provided the electrical design, materials, and installation at discounted rates

- Audio and Computer Wiring: Jim Belanger and Beltronics donated this labor and material

- Heating and AC: David Brassard co-coordinated the installation of the heating system

- Landscaping: Pat Coughlin and the Colonial Garden Club organized the landscape design and materials, including walkways, small stone walls, and plantings